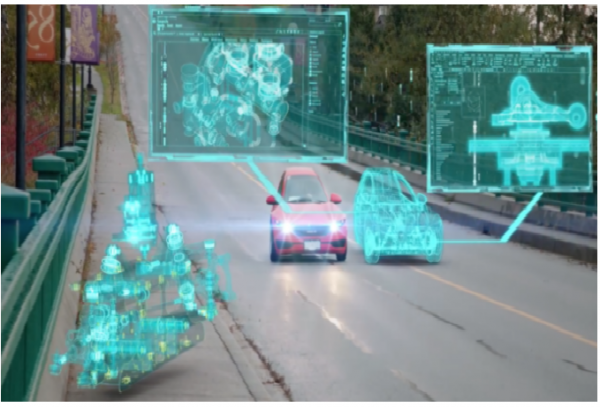

A digital twin is a virtual model of your real plant using real data. Using a Digital Twin makes it possible to analyze your existing plant and look at improvements and the ability to simulate new optimized scenarios to improve productivity.

A digital twin concept has been implemented in various circumstances to simulate things like driverless vehicles, electron flow in iPhones to monitor temperature rise, heating in data centres, and many more. In the New Zealand Manufacturing environment, CNC sees this being applicable in an array of industries from Rocket production, development of products for CNC production, or simulation of new products for production facilities to assist with planning and implementing production.

New Zealand has a long history of innovation, pushing the boundaries of what is possible, and punching above our weight in the global arena. With the development of software that can simulate products before they are built, the development cycle can be considerably reduced and thereby maintain and build New Zealand companies competitiveness in the international market.

Please contact CNC Design to discuss your requirements