Hygienic food handling eliminating the risk of bacterial cross contamination

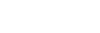

Staubli robots are your industrial robot with state-of-the-art robotics and automation in the food industry. Staubli robots are your best automation choice for robots in food manufacturing as they are washable and can maintain the required high standard of hygiene required for a robot designed for the food industry.

Staubli HE (humid environment) robots are specially designed to conform to international EHEDG guidelines for hygienic food handling, in particular raw protein, and eliminating the risk of bacterial cross contamination. The robotic arm is fully enclosed with smooth washable surfaces and no retention areas. The interior is sealed and pressurised to keep out moisture. The special surface coating is resistant to harsh cleaning chemicals and the wrist is stainless steel. Cables and pneumatic tubes are routed through the arm via connections under the foot to prevent water ingress during wash down.

Robotic process automation applications for Staubli food robots include; carcass evisceration, brisket cutting and deboning in abattoirs, raw meat and fish processing, preparation and presentation of ready-made meals, cheese handling … and many more, wherever there is risk of bacterial contamination.

Contact CNC Design now to enquire about our Staubli robot range to ensure hygienic food handling for your processing plant.

Types of Siemens Controllers

Siemens was a pioneer in industrial automation. Siemens has been operating worldwide since 1847 and in New Zealand for over 150 years. (Siemens New Zealand started with telegraph systems).