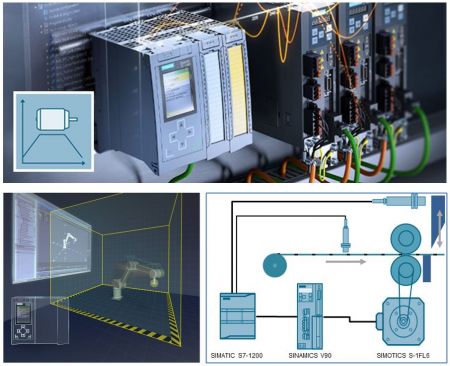

Siemens WinCC Unified HMI system entered the market in 2020, and as the name suggests, it offers a common engineering and runtime platform from simple embedded applications through to full-featured SCADA. Sitting in the middle of this range are the Unified Comfort touch panels, available in 7 to 22 inch screen sizes. Graphics are vector based, offering unprecedented accuracy and elegance of scalability between different sizes of screen and different platforms.

The WinCC Unified HMI system was developed with modern needs for security and interoperability in mind. We believe Unified Comfort Panels (UCPs) strongly meet these needs, while providing a variety of hardware and software options that allow a well-fitting solution to be engineered.

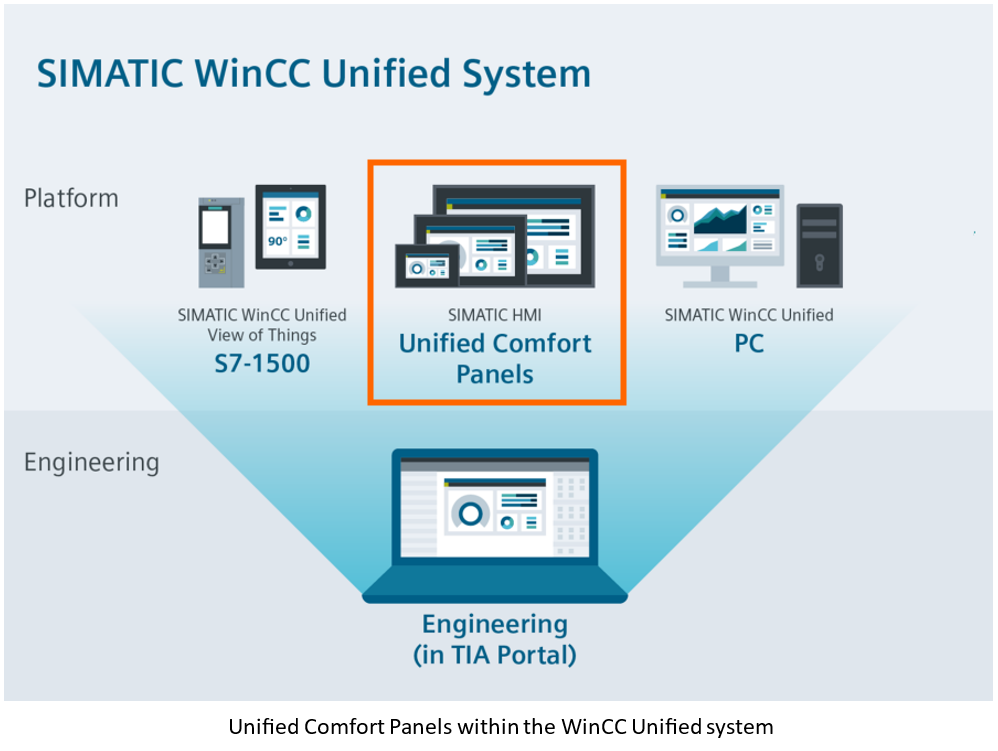

Hardware Variants

A neutral variant has been offered alongside the standard Siemens-branded Unified Comfort Panels. The option of buying without the Siemens logo gives OEMs flexibility with the visual design of their machine.

The SIPLUS Extreme variant provides options for use in harsh environments - particularly corrosive atmospheres, condensation and high altitude.

Finally, Siemens has recently released the Hygienic variant. Designed in accordance with guidelines from the European Hygienic Engineering and Design Group (EHEDG), several features make it suitable for the food industry:

- Tested with industry standard cleaning agents.

- Stainless steel front bezel - polished for ease of cleaning

- Bezel and interface to hardened glass screen has minimised contaminant trap points for hygienic cleanability.

- Splinter protection foil over screen with IK10 impact resistance.

- Replaceable, foodstuff-compatible mounting seal.

- IP69 protection.

CNC Design NZ is a member of EHEDG and the NZ agent for Staubli robots. Staubli’s HE robot range has been honed over many years in accordance with EHEDG guidelines and is now the de facto standard for hygienic open food handling in Europe.

As an EHEDG member, with two engineers having undertaken the ‘EHEDG Advanced Hygienic Design Course’, CNC Design NZ is well placed to assist you with the development of turnkey automation systems or OEM machinery for the food industry.

Secure by Design

Security is an important topic in 21st century automation and was at front of mind in the design of Unified Comfort Panels.

Encryption of project transfer to the HMI, and of HMI-PLC communication is easily configured. Security is managed centrally in TIA Portal for all project devices. The proprietary Linux-based operating system has a built-in certificate manager to facilitate secure remote access to the HMI, and can be configured to disable unused USB/network interfaces.

Encrypting access to/from UCPs was important in a couple of CNC Design’s recent industrial automation OEM support projects involving sensitive systems and data. These measures go alongside others such as network and site protection in Siemens’ “defence in depth” concept for comprehensive industrial security.

Interoperable

In modern industrial automation the ability to interact securely with higher level systems in crucially important, e.g. for data reporting and analysis, or for automatic order processing in flexible manufacturing systems. Unified Comfort Panels offer diverse options in this regard, for example:

- OPC/UA server – e.g. for connection with SCADA systems

- Direct SQL database connection – e.g. for interacting with Manufacturing Execution Systems or Warehouse Management Systems

- Generating Excel or PDF reports, shared via email/external media

- Cloud connection via MQTT

- Customized emails

- Customized communication via Edge Apps, as explained below.

UCPs also offer two methods for secure remote access – the web client interface (which can be accessed from any modern web browser), and a VNC server.

Expandable

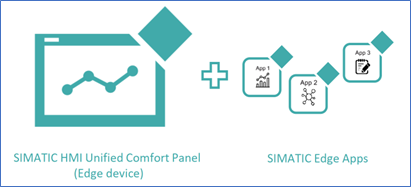

Finally, through the highly innovative Edge Apps feature, the functionality of Unified Comfort Panels can be expanded and customised to the user’s needs.

The user can create their own edge apps using the Siemens Industrial Edge Publisher. Edge apps run in the background and can query runtime data such as tags and alarms. Within the capabilities of the physical hardware, this opens up for OEMs the possibility of adding advanced features on-machine, for example:

- Modelling and controlling complex chemical interactions on process lines.

- Collecting and reporting data on machine use and faults, for the customer’s OEE analysis and/or feedback to the OEM for closed-loop product design.

- Data analysis for preventative maintenance.

- Apps to interface with Manufacturing Execution Systems (MES).

Siemens has also published Simatic Edge Apps for UCPs, which solve common automation tasks:

- Performance Insight – implement KPIs and OEE analysis

- Notifier – sends notifications about the process to user’s smartphones

- Energy Manager – optimize energy consumption, costs and CO2 emissions

These ready-to-use apps augment the capabilities of a UCP and provide functionality that would typically only be seen on SCADA-type systems.

Conclusion

In this article, we have outlined some aspects of Unified Comfort Panels that we believe place them at the leading edge of the industrial touch panel market. Used appropriately within an automation system, UCPs can provide substantial value. As a Siemens Solution Partner, CNC Design NZ can assist you with incorporating them into your next OEM machine development or end user automation solution. CNC Design NZ specialises in specifying, supplying and supporting your Siemens parts throughout their life cycle. Contact us if you have an application that could benefit from Unified Comfort Panels.