One advantage of Siemens’ motion offering in the Simatic controller range is how flexible and easy it is to integrate with all kinds of hardware.

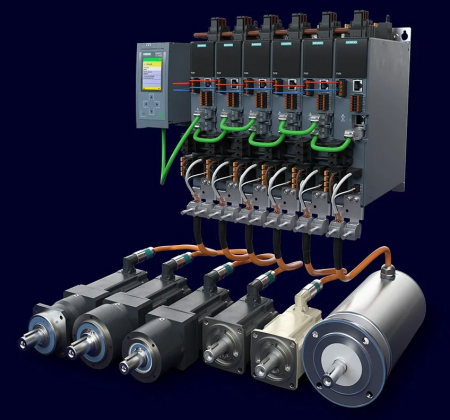

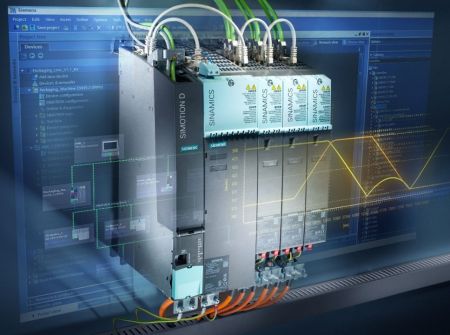

All current S7-1200 and S7-1500 PLCs provide built-in motion control capabilities. This ranges from basic positioning, through to advanced features like camming and safe kinematics with the S7-1500 TF controllers.

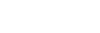

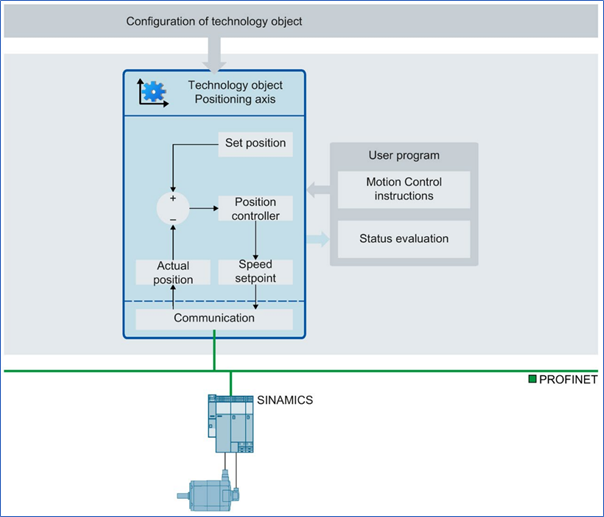

The sizes of supported systems vary from a few axes to over 100, but all are built from Axis Technology Objects (T.O.s). Axis T.O.s translate between hardware and the Simatic motion kernel to allow different types of devices to be controlled in coordination.

Drive systems can be controlled with Ethernet communication over Profinet. They can also be hard-wired to Siemens IO such as analogue output modules and encoder input modules. If these standard interfaces are not compatible, virtual signals can be generated to accommodate any drive system using Data Blocks. This allows, for example, the connection of analogue (4-20mA) encoders, Profibus devices, or even encoder emulation.

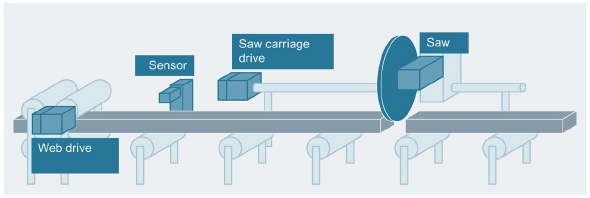

CNC Design NZ has implemented cost-effective retrofits using Simatic motion control due to Axis T.O.s making it easy to re-use existing hardware. For example, an upgrade to a flying saw on a panel line greatly improved the accuracy of the system, with only the PLC, HMI and IO needing replacement; the existing Mitsubishi drives and servomotors were re-used. This kind of approach allows for a staged upgrade by first installing a Siemens NZ controller, and later on replacing the drive systems with Siemens S120, S210, V90 or S220 servo systems. Or for basic applications Siemens G120C or G120 VSDs. PROFIsafe is available on all Siemens NZ drives except the V90, so a safety upgrade on the machine in question can easily be implemented at the same time.

CNC Design is a Siemens New Zealand Solution Partner for automation and drives. Operating in NZ for over 30 years, distributing Siemens parts and working exclusively with Siemens control systems. CNC Design NZ is ideally placed to specify, supply and support your Siemens parts throughout their life cycle. We can offer a motion control platform for every need. Contact us to discuss your next automation project.